As the global energy industry steadily transitions toward more sustainable practices, Client Energy Refinery has emerged as a forward-thinking leader by integrating renewable feedstocks into its operations. This strategic shift supports cleaner fuel production and aligns with long-term environmental goals but it also presents complex engineering challenges, particularly in the area of emissions management.

One of the most critical technical issues faced during this transition was a significant increase in carbon dioxide (CO₂) concentration within the acid gas stream. This elevated CO₂ level, primarily driven by the increased use of renewable feedstocks, began to impact the performance and reliability of the Sulfur Recovery Unit (SRU), leading to reduced efficiency and difficulty in maintaining regulatory emission standards.

What began as a feasibility study aimed at resolving sulfur recovery constraints and ensuring compliance with stringent emissions regulations eventually evolved into a comprehensive engineering initiative. A-One Engineering Consultant LLC was brought on board to lead the project from initial concept development to full execution, including both the Basic Engineering Package (BEP) and the Detailed Engineering Package (DEP).

Upon evaluation, it was evident that the rising CO₂ load was diluting the acid gas feed, leading to unstable SRU combustion temperatures and decreased sulfur recovery efficiency. These conditions compromised the plant’s ability to stay within its permitted emission limits—especially during variable load operations. The need for a robust, technically sound solution was clear.

In collaboration with its technology partner, Client Energy explored several mitigation strategies and ultimately identified membrane-based gas separation as the most effective path forward. The solution involved a multi-layered approach:

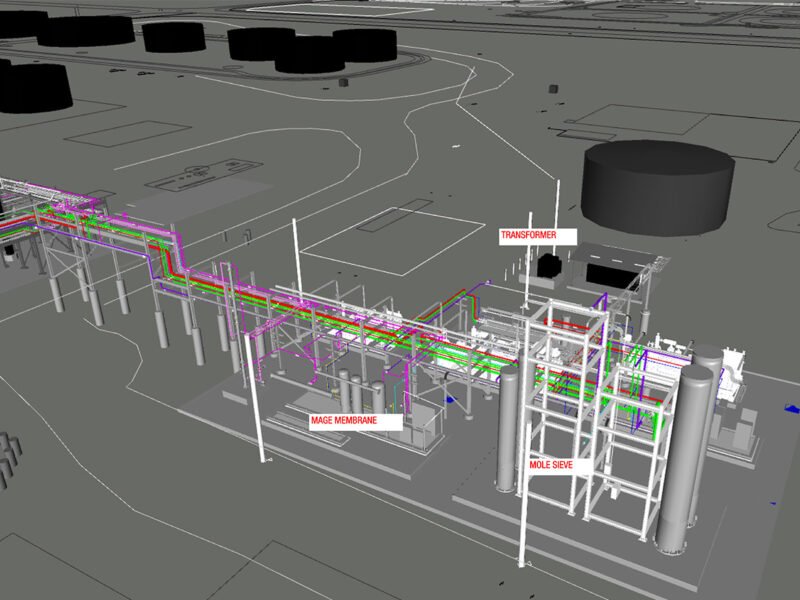

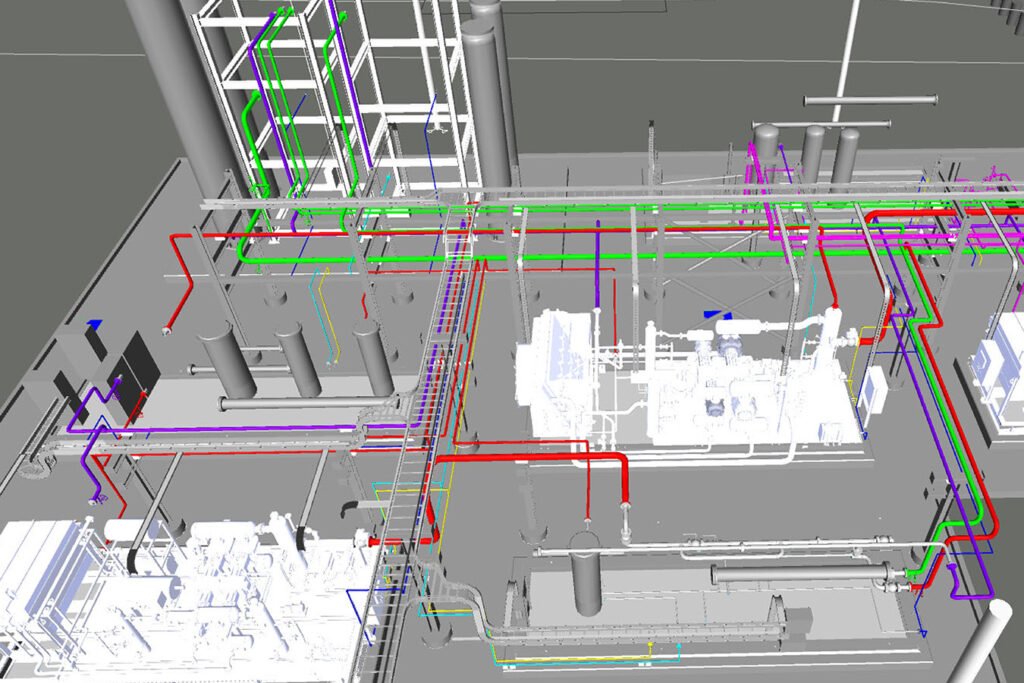

Upstream Intervention: Implementation of a Membrane-based Acid Gas Enrichment (MAGE) system before the SRU to reduce CO₂ concentrations and improve feed gas quality.

Downstream Treatment: Deployment of Membrane Tail Gas Treatment (MTGT) followed by Advanced Tail Gas Treatment (ATGT) to capture residual sulfur compounds and minimize overall emissions.

Control System Optimization: The existing SRU control architecture was recalibrated and integrated with the new systems to ensure seamless operation and dynamic response to changing feedstock conditions.

A-One Engineering Consultant LLC played a pivotal role throughout the lifecycle of this project, delivering not only the engineering designs but also supporting installation planning, operational integration, and control system tuning. The successful implementation of this solution restored SRU reliability, enhanced sulfur capture efficiency, and most importantly, ensured the refinery remained well within environmental compliance thresholds.

This project serves as a testament to the ability of A-One Engineering Consultant LLC to deliver innovative, technically rigorous solutions tailored to the evolving needs of the energy sector—particularly in the context of decarbonization and renewable integration.